|

Didjeridu

manufacture in Eastern Arnhem Land

These few images

help to demonstrate the basics steps in the cutting and fashioning

of a traditional instrument. The basic methods are the same

for across the Top End, only the finer points of manufacture

(such as tree selection which will determine the regional

style of the instrument) differ.

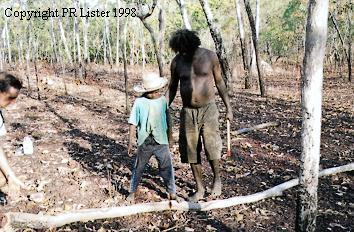

The maker is Roy

Burnyila of Ganalbingu descent, Ramingining, eastern Arnhem

Land.

A

suitably shaped and hollow living tree is selected. This one

is a bloodwood (Eucalyptus miniata) growing very close

to the base of a stringybark (E. tetradonta). The flitch

of bark removed near Roy's hand is where he tested the degree

of hollowness of the trunk prior to cutting. Trees that are

determined to have too small or too large a cavity are left

standing. Yolngu are particularly adept at selecting suitable

trees in this manner.

The termites are

extremely efficient at consuming the timber, so fairly large

cavities exist in relatively small trees. Once it has been

cut around the base it doesn't take much effort to fell.

Once felled, the

craftsman determines at which point to cut what will become

the proximal (mouthpiece) end. That's my bald patch you can

see on the left, and Roy's son, Alvin wearing my hat.

click on photo for enlargement

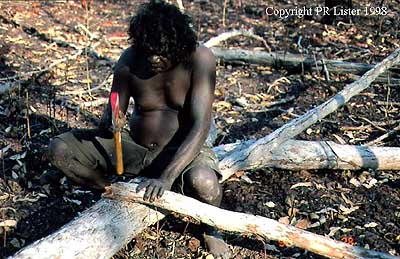

Once cut, the instrument

is banged on its' end a few times to remove any loose termite

frass, soil and wood. If there's a blockage, or if something

get's stuck during this process, then a thin sapling can be

inserted and used to clear the blockage. That happened in

this instance.

click on photo for enlargement

The mouthpiece

is trimmed to remove rough material. At this point, the instrument

is already playable!. The careful choice of tree means that

the mouthpiece is already close to the desired diameter. Here

is a fundamental difference between traditional manufacture

such as this and the way in which most didjeridus from other

parts of Australia are being made. Many of the didjes I see

that are not made this way have hollows too large to be used

as is, and as such have large amounts of beeswax applied to

them to reduce the diameter to a playable size. If wax is

applied by Roy, it's just a thin smear for "comfort".

click on photo for enlargement

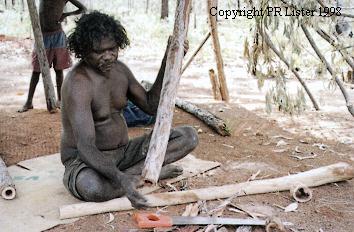

The bark is stripped

on the spot or back home (as in the final photo).

click on photo for enlargement

A short break and

a blow to test the sound - this turned out to be an excellent

instrument.

Here Roy's trimming

the length and cleaning out any remaining loose material.

The "skinned" (de-barked) instrument lying in front of him

is the instrument that was being cut in the previous shots.

This page is Copyright

PR Lister 1999. Please feel free to link to this page if you

wish, but you must contact

me if you wish to use this material in any other way.

Special thanks

to Roy Burnyila and GL for permission to use these images

and for taking me with them on the day.

|